Our Team

We heavily recruited this year from local area schools and WACO affiliated FIRST Lego League team. Our team grew to 11 members while losing one senior and two others dropping off.

Preston

Lead Engineer

The oldest member of the team, Preston works to make sure everything runs smoothly.

Gavin

Software Developer

Powered by Caffeine, Gavin makes sure our robot has its head on straight.

Jordan

Lead Technician

With a mastery of everything mechanical, Jordan leads the assembly of all mechanisms.

Eric

Engineer

The team member with the most dance moves, Eric helps design the robot in CAD.

Nick

Engineer

The most athletic team member, Nick helps design the robot in CAD.

Grayson

Technician

Mixing black and white, Grayson helps make sure the robot is assembled correctly.

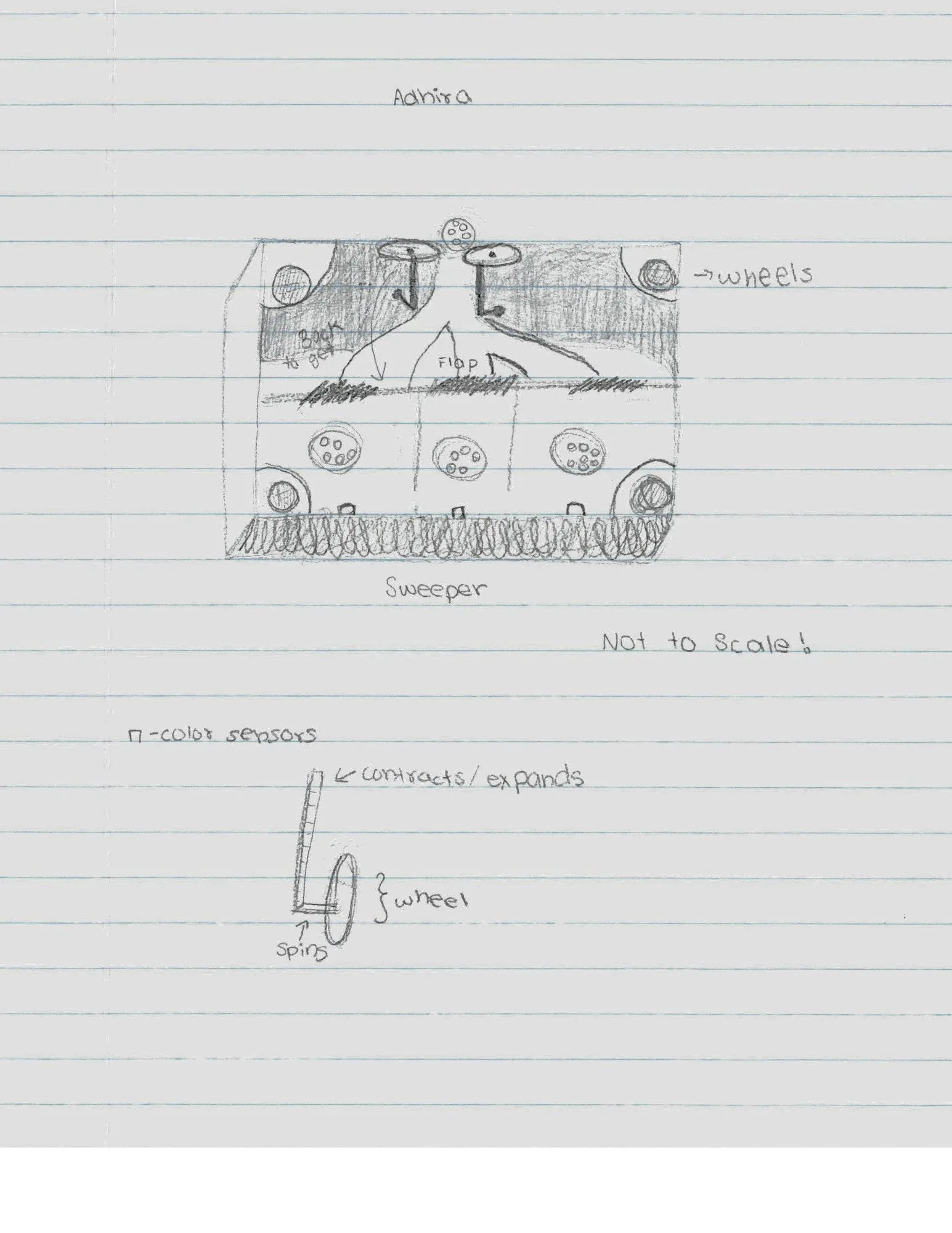

Adhira

Technician

One of our newer recruits, Adhira helps make sure the robot is assembled correctly.

Maddox

Technician

Our youngest team member, Maddox helps make sure the robot works correctly.

Pellum

Technician

One of our newer recruits, Pellum helps make sure the robot works correctly.

Kemper

Technician

Right along with Pellum, Kemper helps make sure the robot works correctly

Jude

Technician

Coming up with off-the-cuff ideas, Jude helps make sure the robot works correctly.

Asher

Technician

Coming up with off-the-cuff ideas, Asher helps make sure the robot works correctly.

Sponsors

Without these generous sponsors, #5140 would not exist as a team. Thank you!

WACO Education Center and Air Museum is the primary sponsor and namesake for #5140. From providing the bulk of the funding for the team, they provide the new facilities, FTC team fees, equipment, tools and training field. Without their generous support and leadership, #5140 would not exist.

Collins Aerospace generous donation to the newly established WACO Learning center has provided #5140 with beautiful team room to build and collaborate.

Radiance Technologies sponsored the team for a second year. Their assistance with team membership greatly helps us in our ability to recruit new members.

Second year sponsor, Canvas has directly assisted in the purchase of parts and equipment.

Outreach: Internet and Engineers

Letting people know we’re here.

Long overdue, we created a YouTube channel! Here, we post updates on all of our testing and building to share with the world. In addition we created a website: wacoaerobotics.synology.me Here, we post our project portfolios and daily updates as to what we do at WACO Aerobotics.

While we upload the internet, one of our seniors (Preston) did some manual scouting. The most notable of which is reaching out to engineers at Canvas. Preston visited their facility at Wright Patterson Air Force Base and discussed design with the engineers. There, he learned about the strengths and weaknesses of 3D printing. In addition, he learned some tips on heat set inserts, which we use to hold our robot together.

Outreach: T-Shirt Cannon and Partnership with Miami East

Letting people know we’re here. With T-Shirts

At the end of INTO THE DEEP, we saw Van Wert’s robotic T-Shirt cannon, and decided we wanted to make our own. Over the summer, we set to work taking some old aluminum extrusion and electric scooter motors to build our robot. Along the way, we caught the attention of both the Fletcher Fire Department and the science department at Miami East High School.

The Fletcher Fire Department was kind enough to donate air tanks to power the cannons. Meanwhile, we took the frame of the cannon to a convention at Wright Patterson Air Force Base on behalf of the Miami East Science Department. There, we showcased our engineering skills in the field of robotics, as well as a bit about FIRST! As we partnered with East, they were willing to provide the electronics and plumbing to fire the cannon.

Thanks to Miami East’s help, we had all the components we needed, and finished the cannon. To return the favor, we fired T-shirts at several football games and band festivals to show what FIRST is all about.

Between football games, we took the cannon to WACO Airfield, the host organization of our team. Here, we fired shirts at their local Fly-In, where hundreds of people gather together to see the museum.

Pre-Season

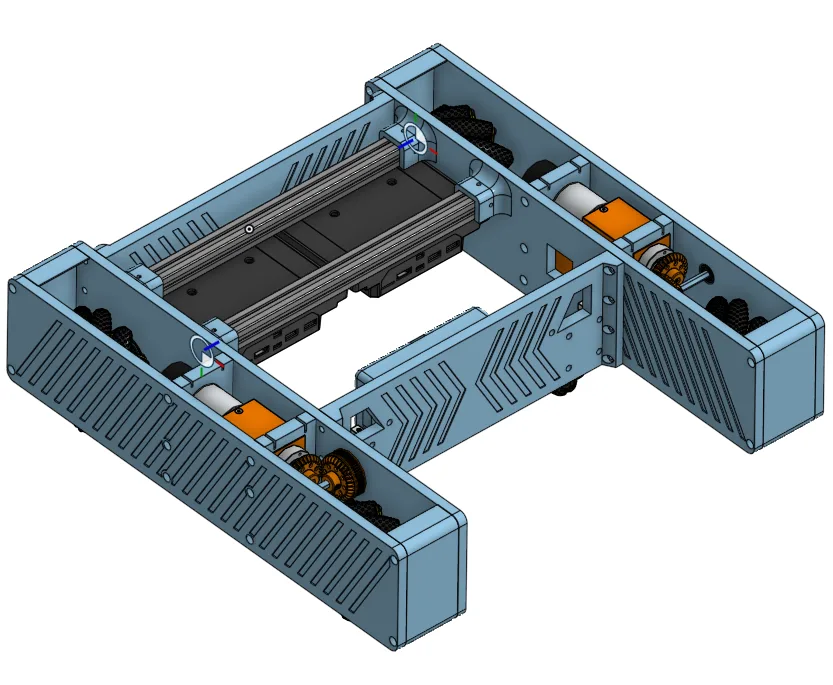

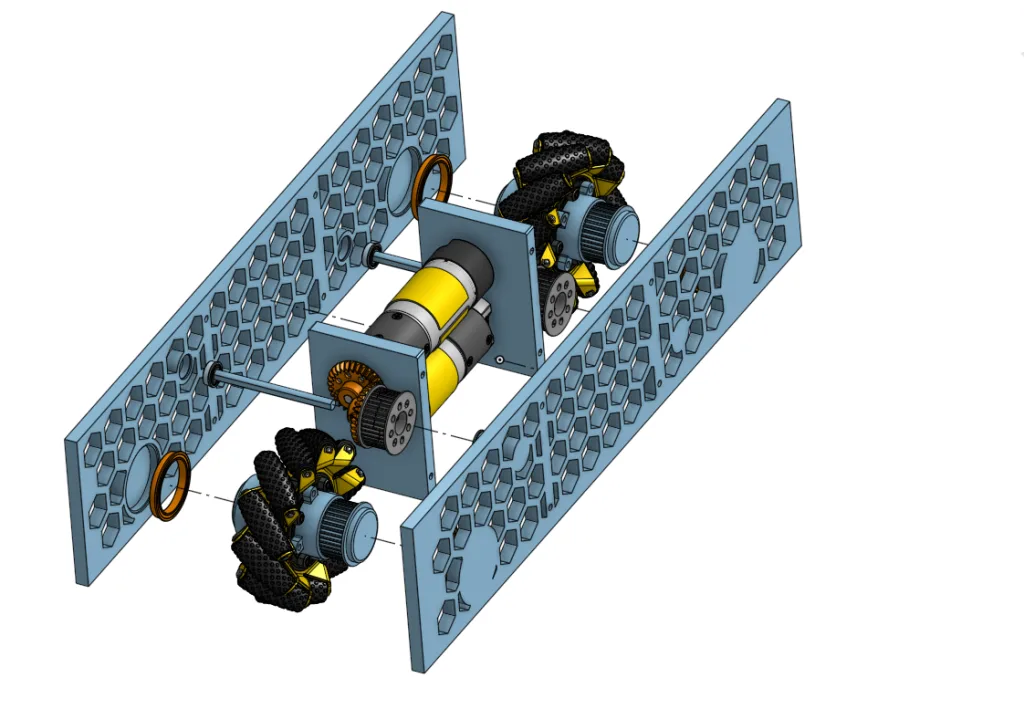

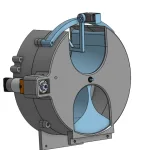

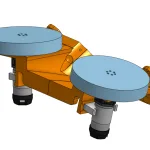

In his spare time over the summer, Preston designed a 3D printed drivetrain, which was inspired by 10084 – Team Calamari

T

This drivetrain utilizes a belt and pulley system to pack the drive motors on the side of the robot, leaving room for other components.

Brainstorming

Getting Ideas Out There

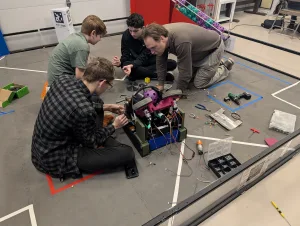

Prior to season start, the team tested various base construction options, specifically with 3D printed components. Heat inserts connected designed and printed walls and then were tested for strength.

Results were recorded on video and uploaded to our YouTube channel.

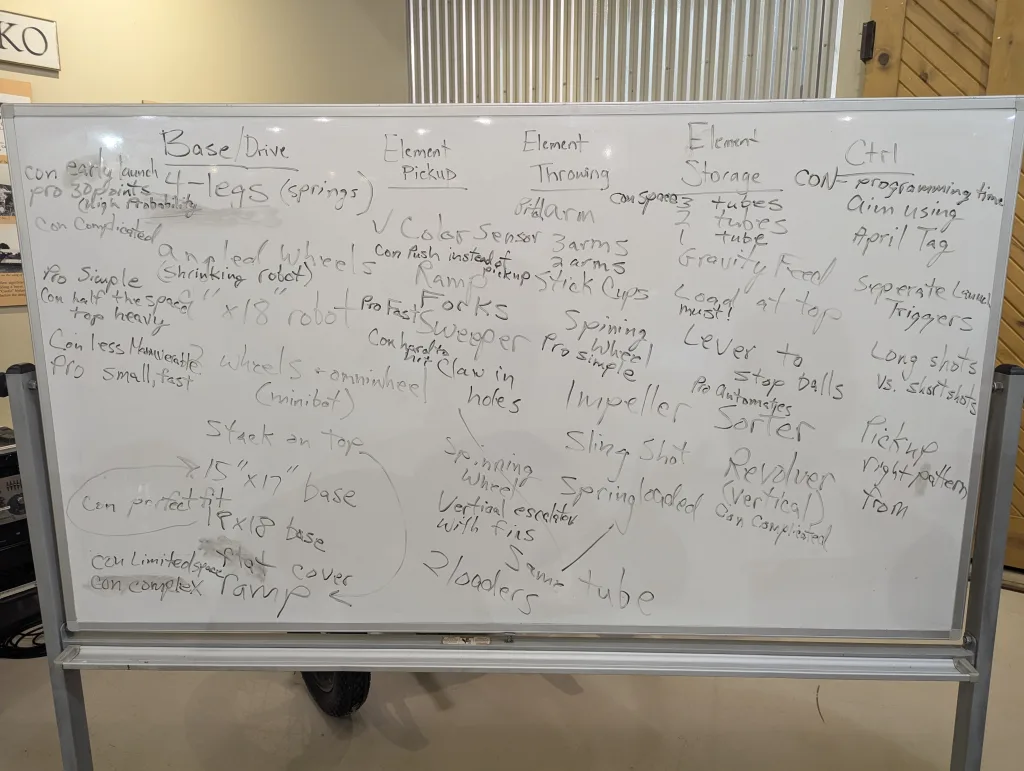

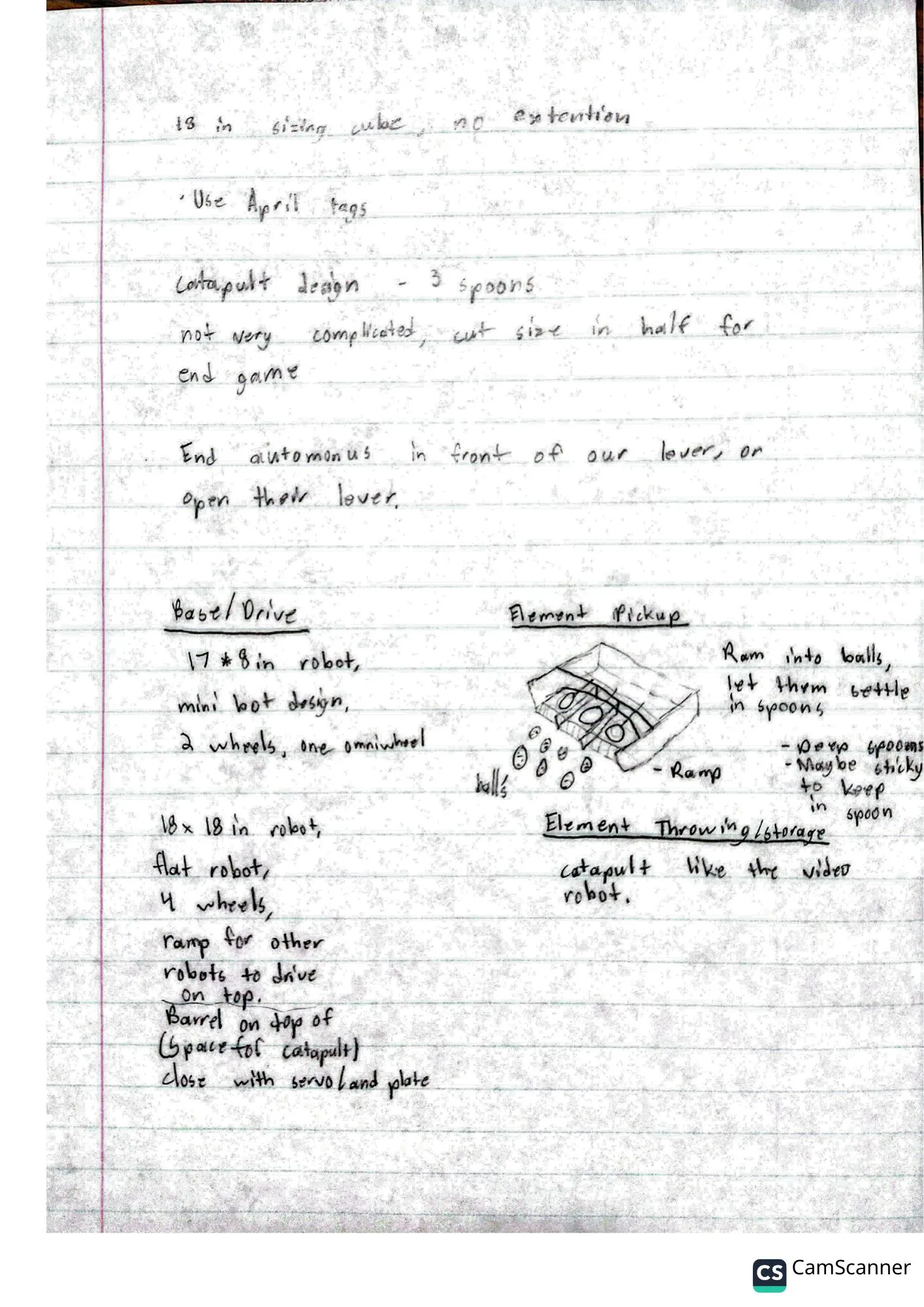

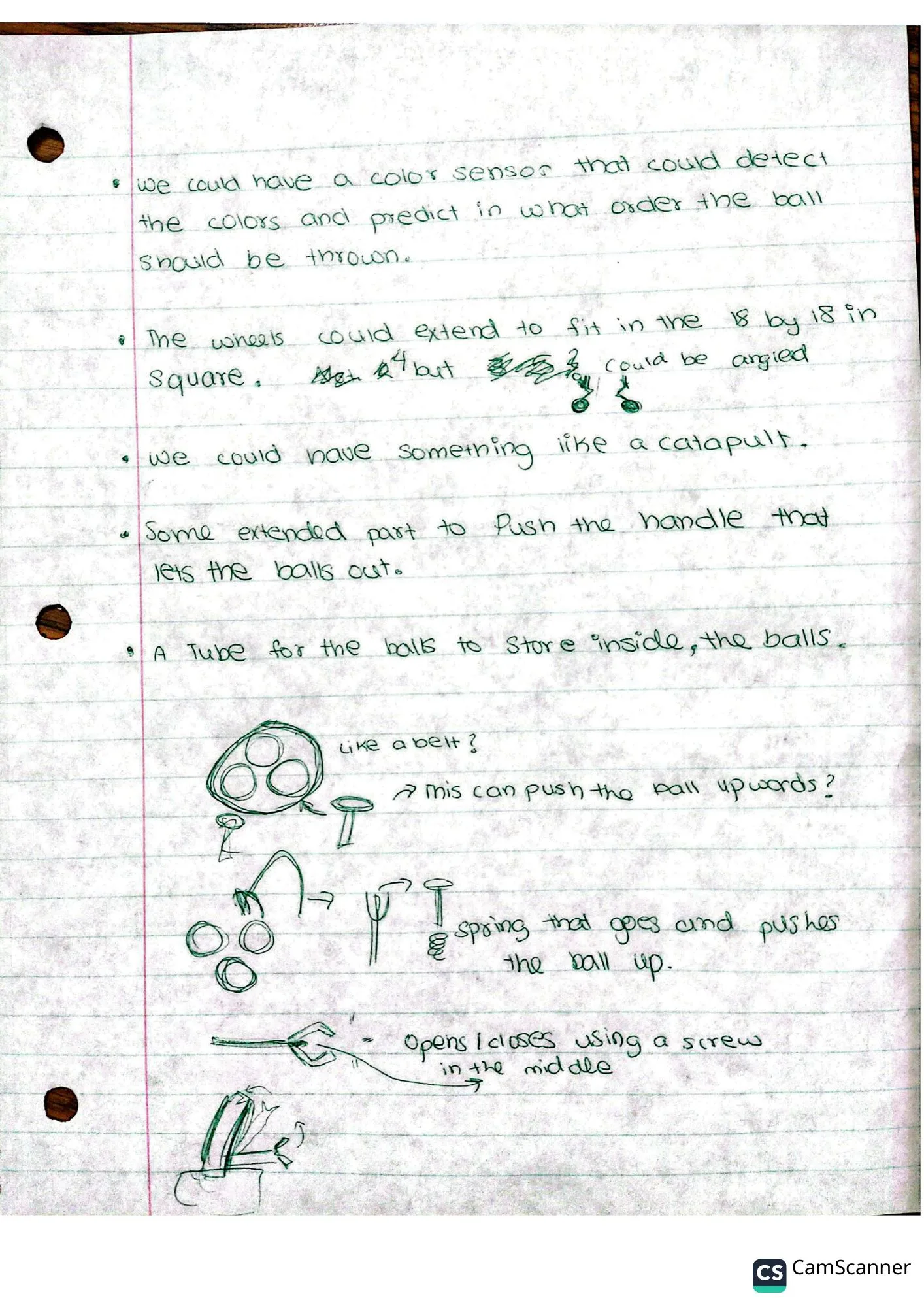

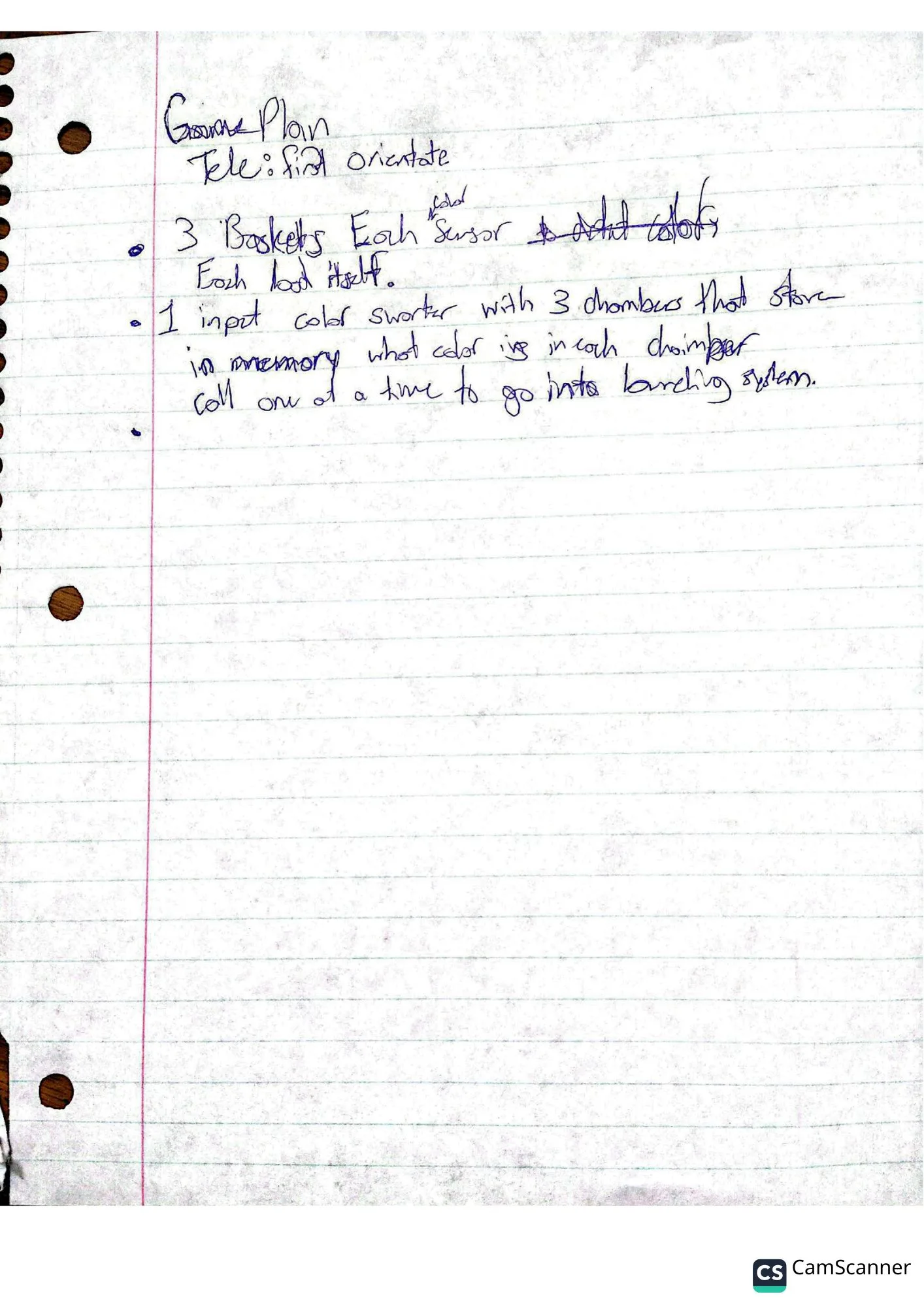

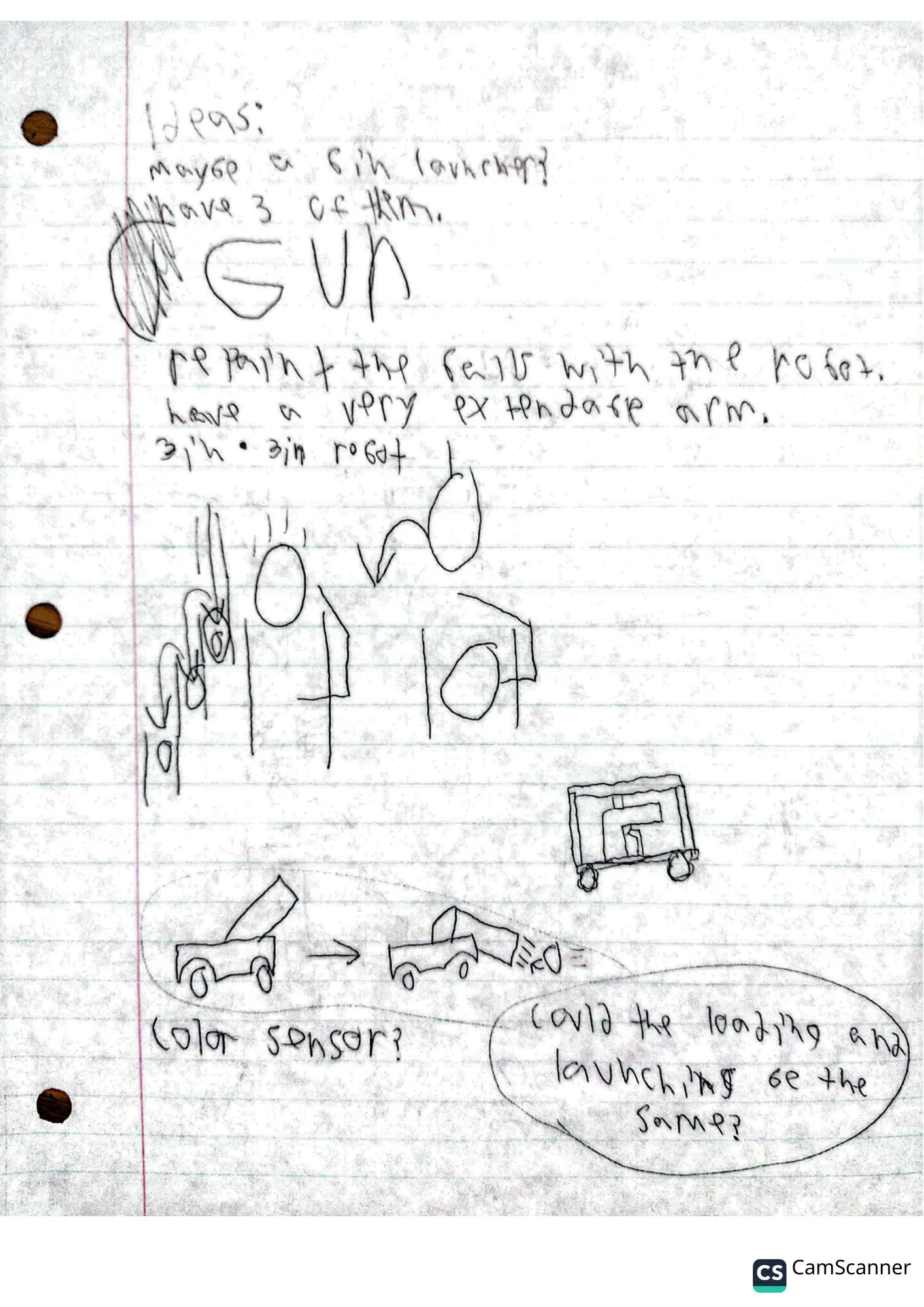

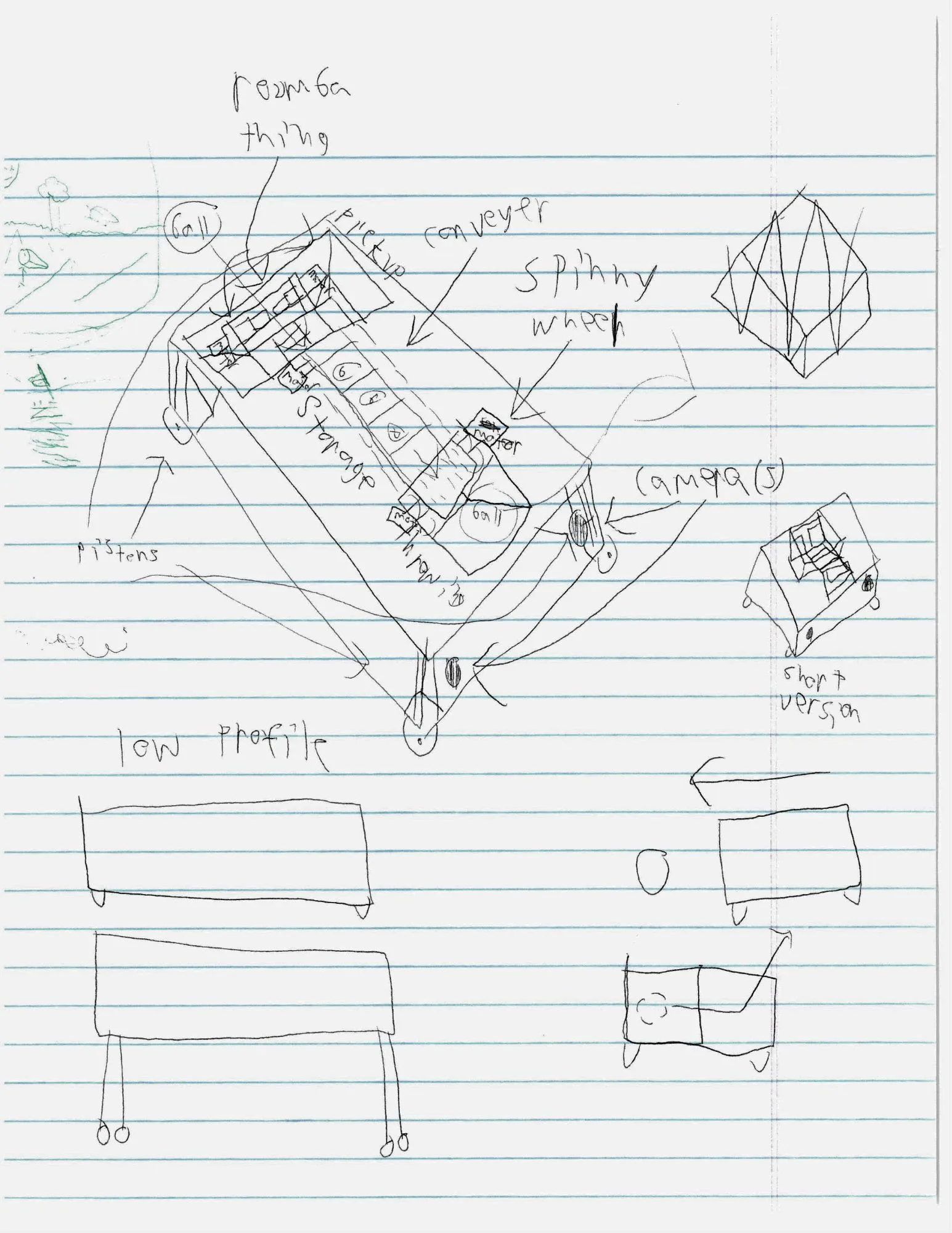

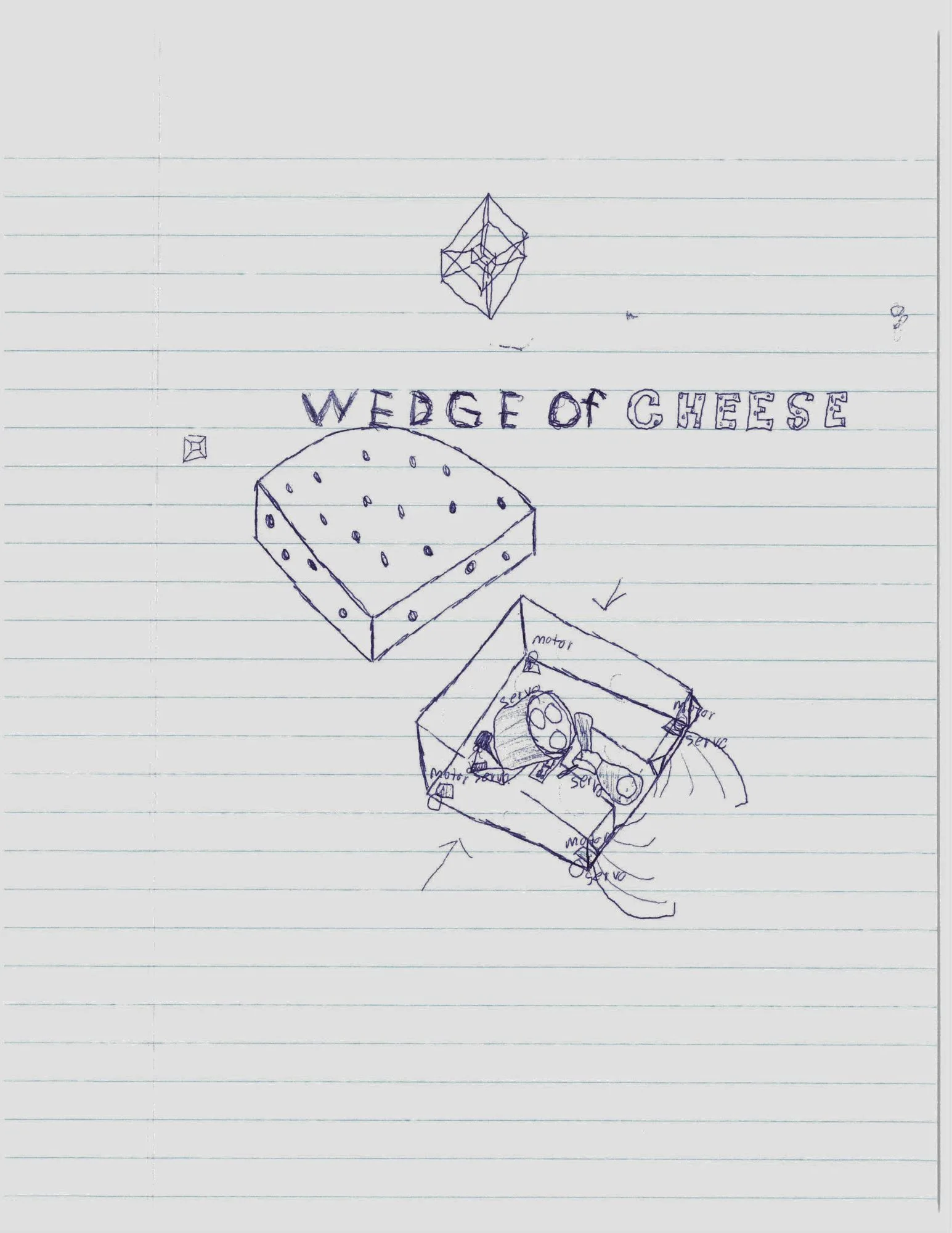

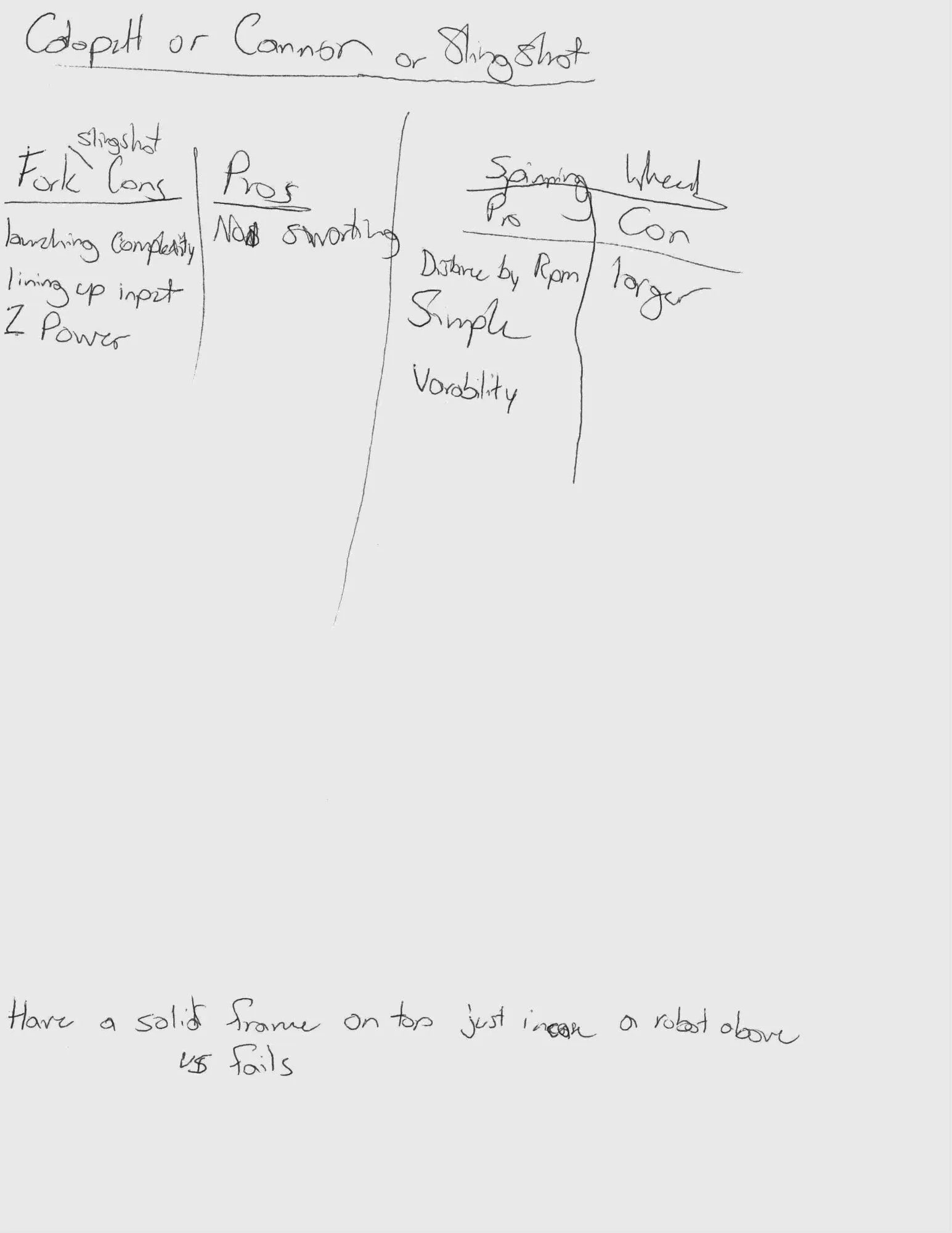

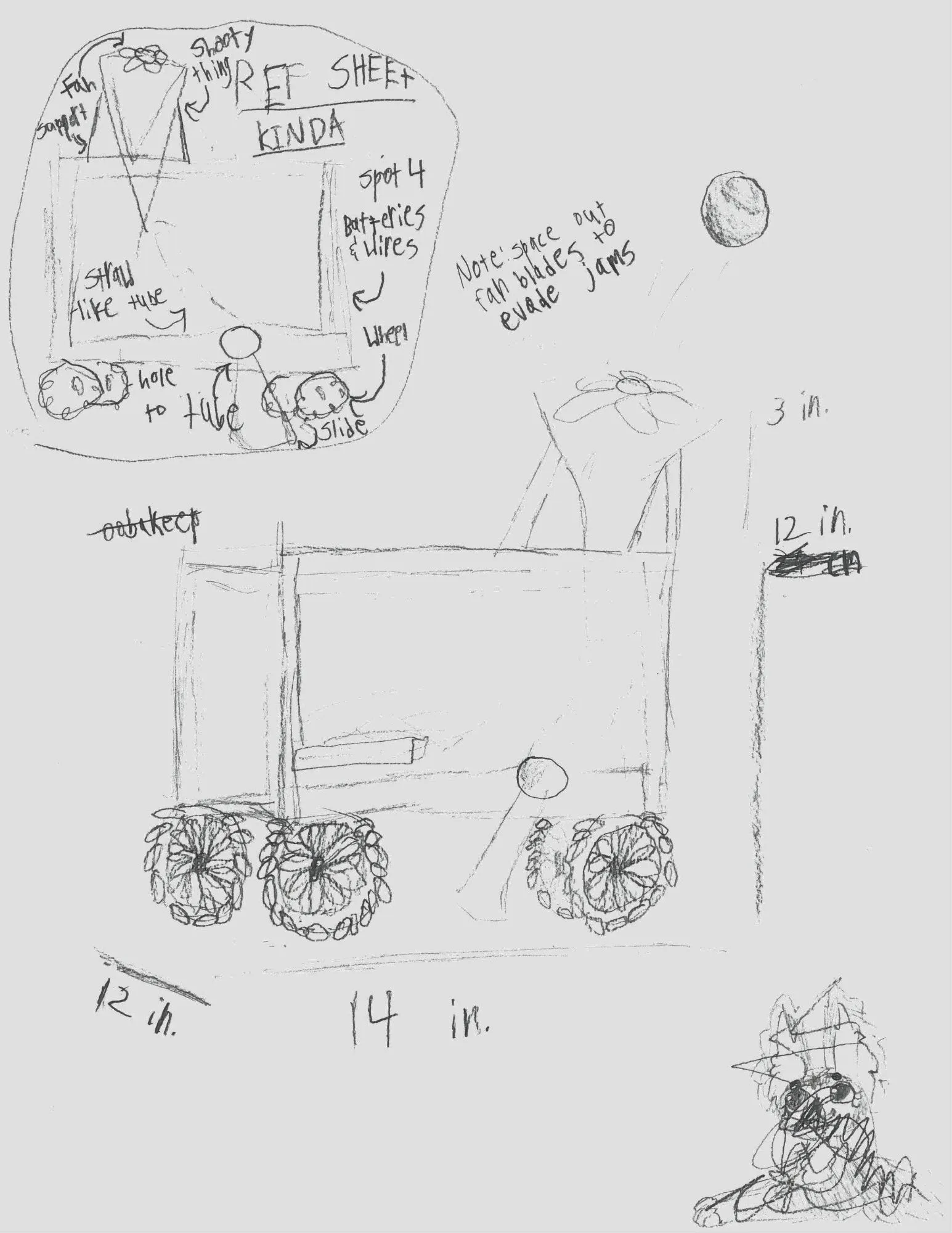

After attending the DECODE kickoff event, the next practice consisted entirely of a brainstorming session. The team threw out ideas for Base/Drive,Element Pickup, Element Throwing, Element Storage and Control. These items coincide with the point award system during each match.

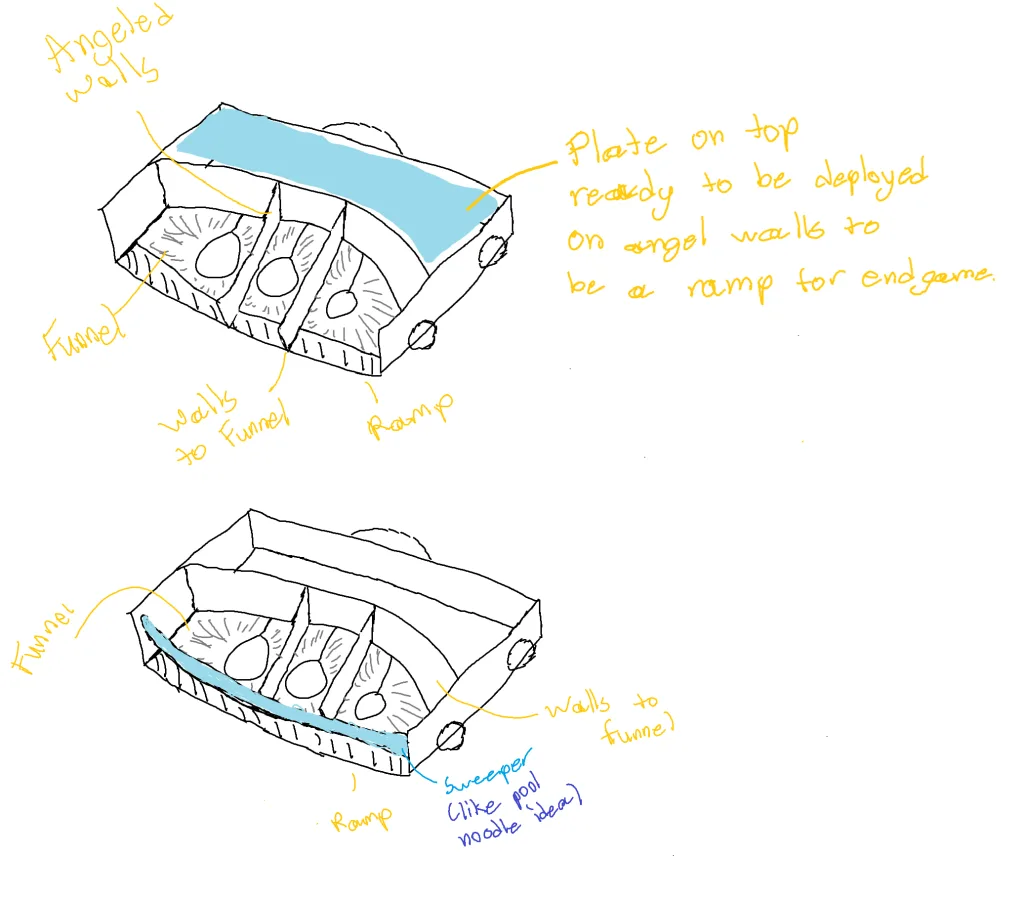

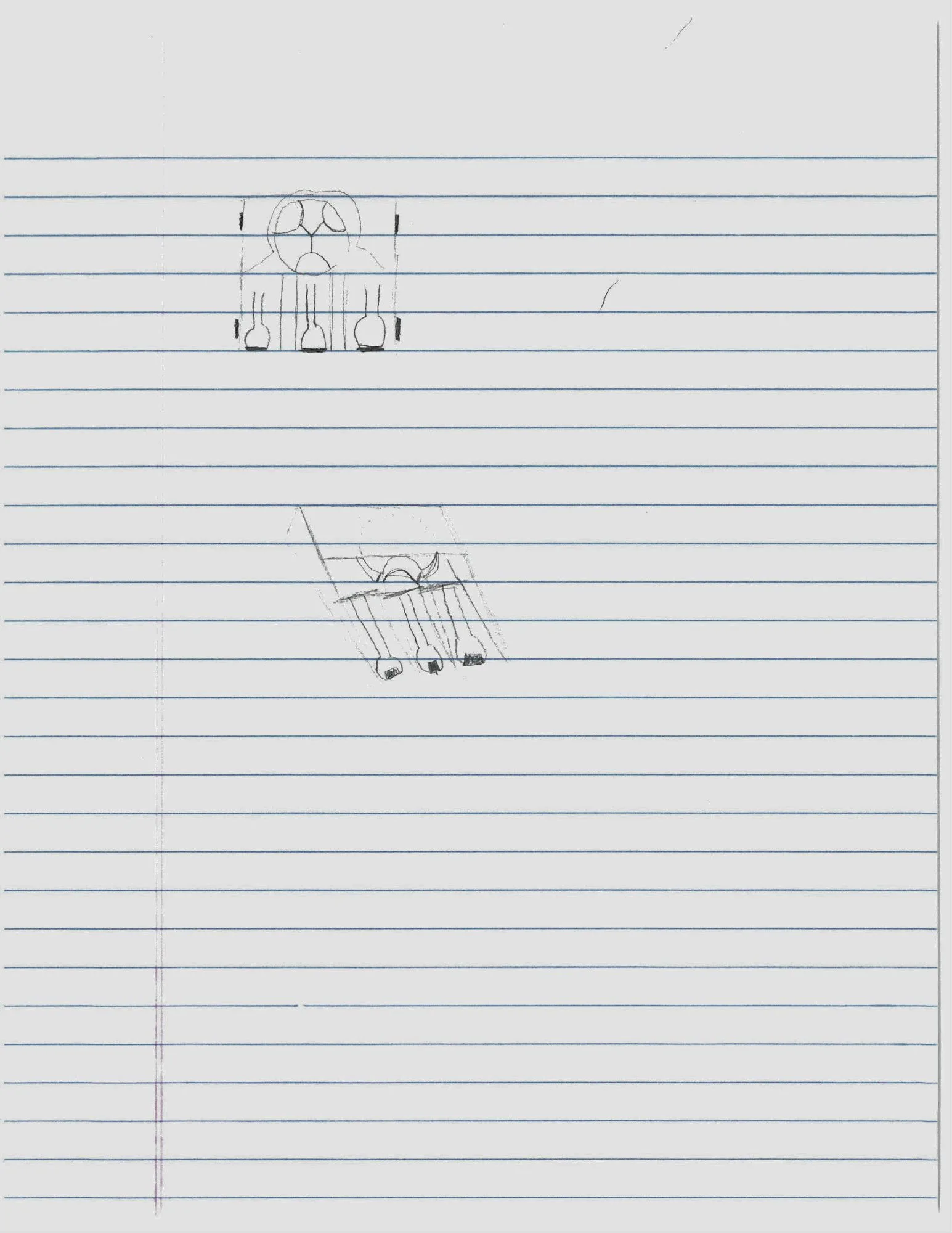

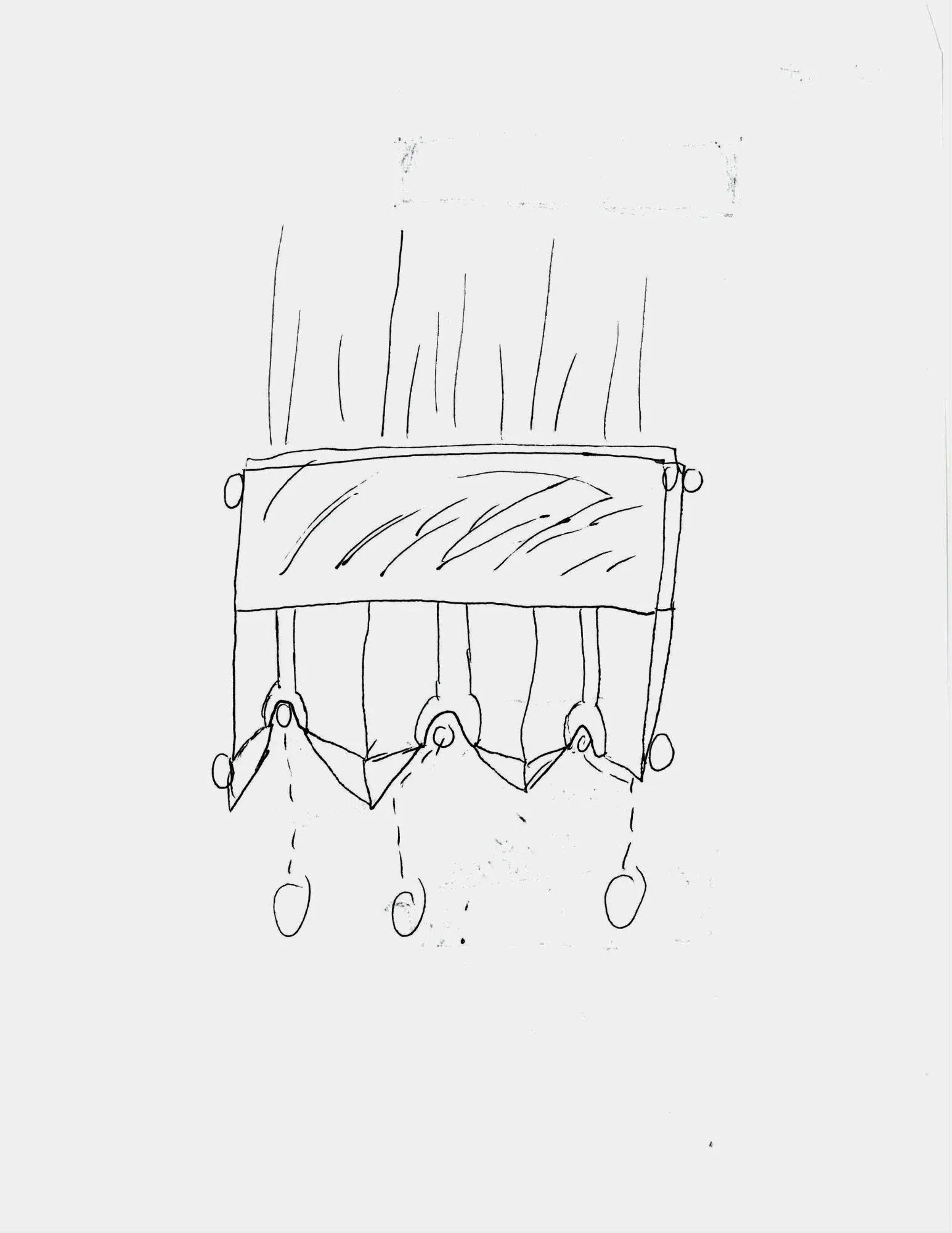

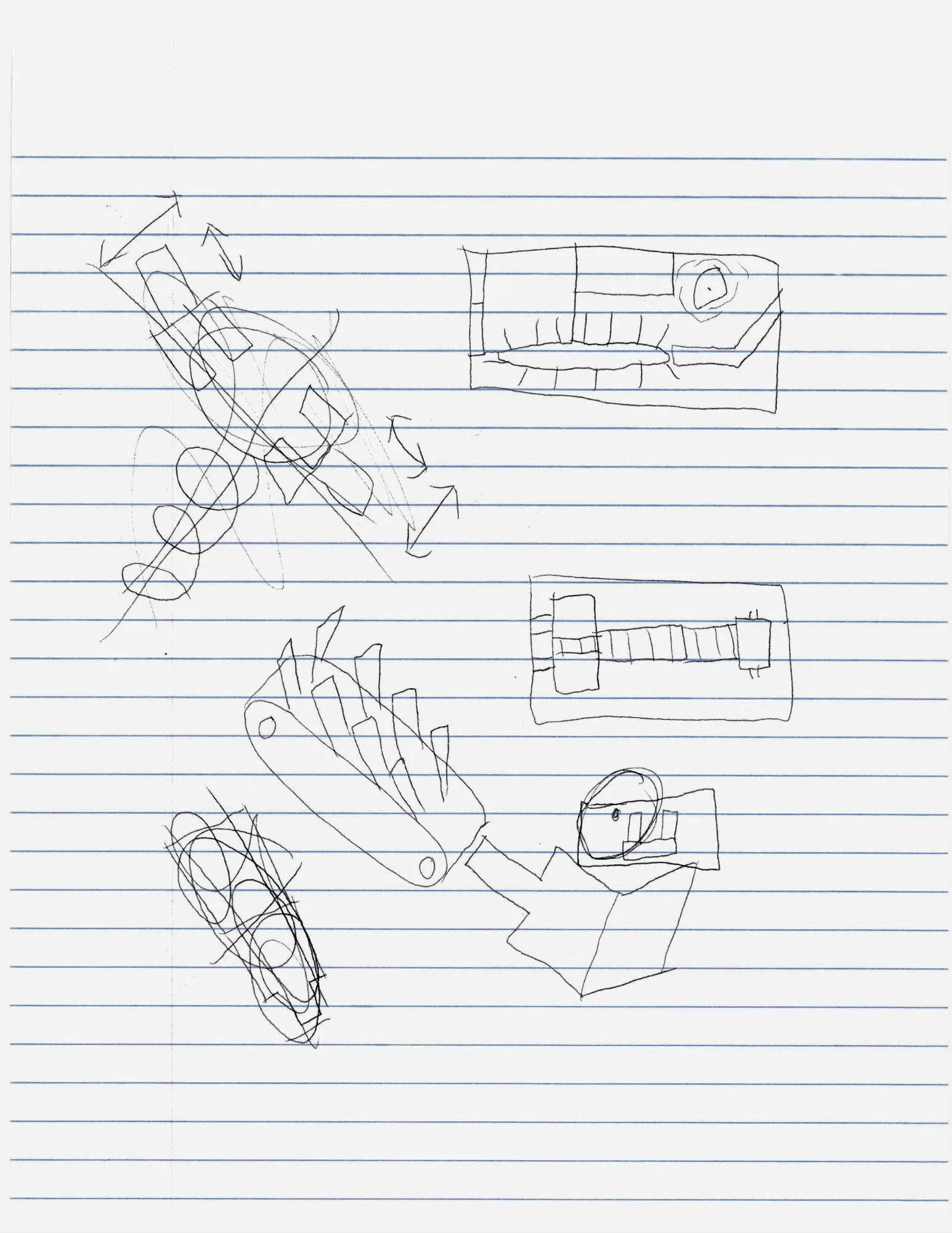

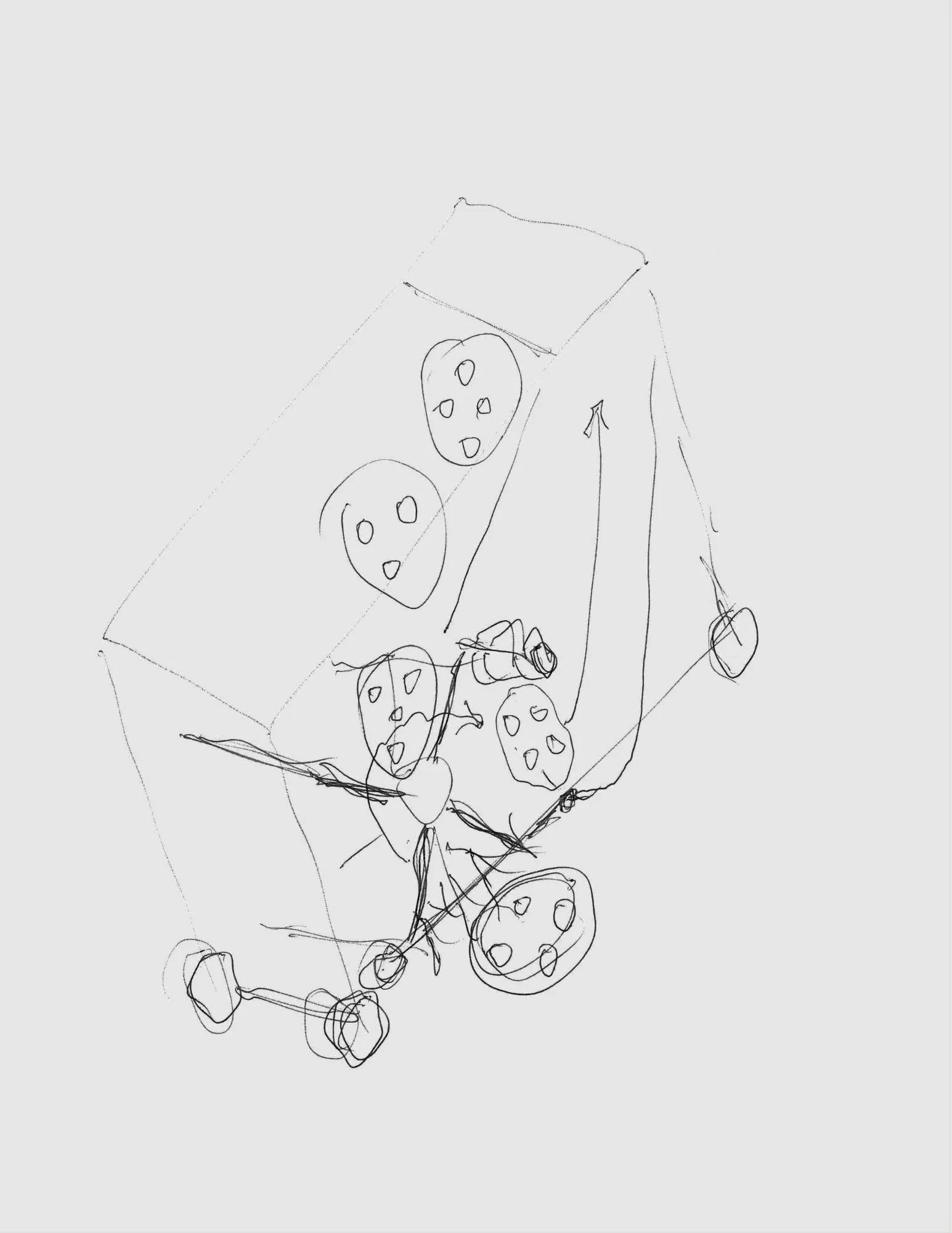

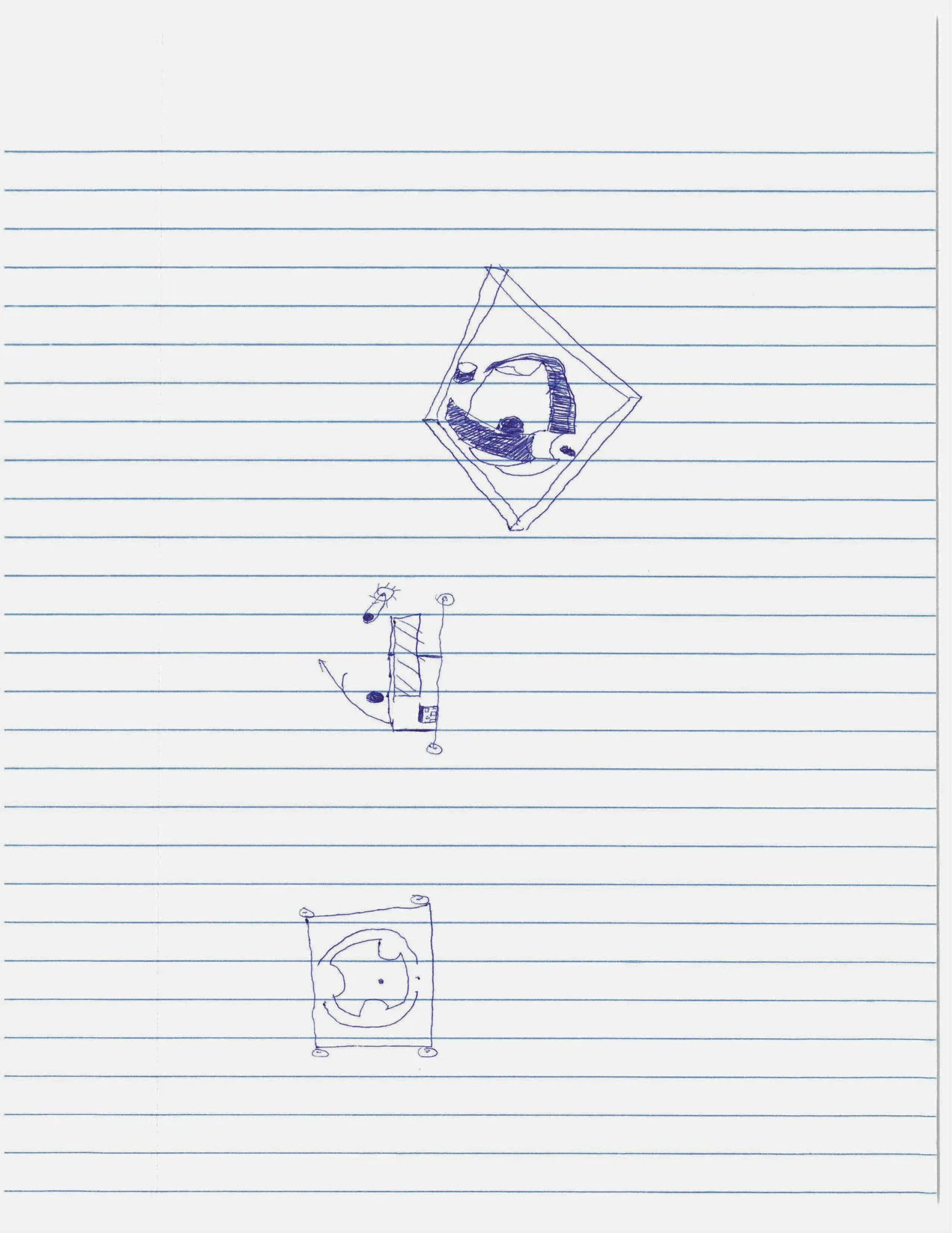

The team documented their thoughts on notebook paper during a 10 minute solo design.

Some players drew out their ideas on paper instead of just words.

We then took those drafted ideas, eliminated what we didn’t think would work and drafted robot designs up individually.

After going through our designs and giving pros and cons of each, we ended up with two types of robots: tall/skinny, flat/wide.

Design

Plan the work, then work the plan.

After the brainstorm, we narrowed down our robot’s concept to utilize 4 main components:

- A rubber-band roller to pick up artifacts

- A “revolver” mechanism to sort artifacts

- A two-wheeled pitching machine to fire artifacts

From there, we created models for each component in OnShape, then attached them to the pre-existing drivetrain model. After that, we added several miscellaneous items such as control hub mounts.

Testing

Does the Plan Work?

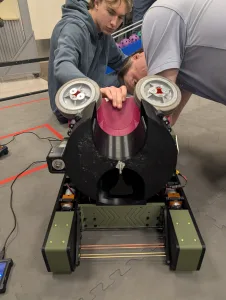

As we built our prototypes, we had to test them to make sure that they are effective. In doing so, we build a test stand to experiment with how we launch artifacts.

Other than the launcher, we did a ton of testing with the robot bolted together, which revealed a huge flaw in our workflow! Since we assembled everything and then tested it, swapping out components became a huge pain. Additionally, we were trying to integrate components before testing them individually, which made a whole mess of our process. Moral of the story: break the problem into pieces, then test each piece before assembling it.